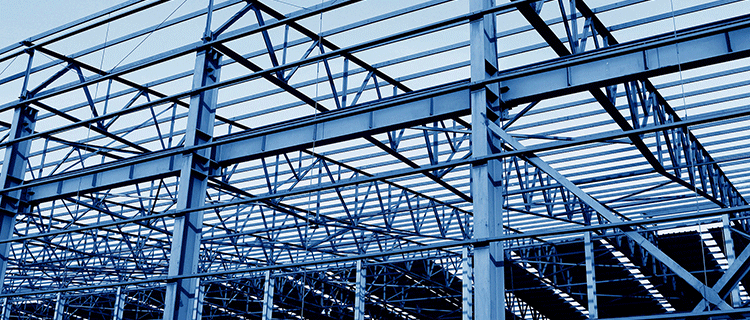

Steel For Construction

Structural steel is a popular construction material, often used alongside concrete to create impressive and long-lasting buildings. Its versatility, sustainability and flexibility are some of the main reasons for its use, as well as being a very cost-effective material. With a high strength-to-weight ratio, steel can often provide a solution where other materials are unsuitable. Let’s look at some of these advantages and how they can be incorporated into the design of a building to overcome specific issues.

In the project and application area, the team should have information about the steel construction and its compatibility with the complementary elements in order to produce solid and high quality structures. Because steel construction systems, unlike other construction systems, arise as a result of combining many elements, most of which are produced in the factory, both in size and material differences from each other. Therefore, in the design of steel structures, the harmony of the carrier system and the integral elements and their detailing are very important. Erdağ Metal company shows the necessary sensitivity with its professional team and quality control unit.

For buildings

- Structural sections: these provide a strong, stiff frame for the building and make up 25% of the steel use in buildings.

- Reinforcing bars: these add tensile strength and stiffness to concrete and make up 44% of steel use in buildings. Steel is used because it binds well to concrete, has a similar thermal expansion coefficient and is strong and relatively cost-effective. Reinforced concrete is also used to provide deep foundations and basements and is currently the world’s primary building material.

- Sheet products: 31% is in sheet products such as roofing, purlins, internal walls, ceilings, cladding, and insulating panels for exterior walls.

- Non-structural steel: steel is also found in many non-structural applications in buildings, such as heating and cooling equipment and interior ducting.

- Internal fixtures and fittings such as rails, shelving and stairs are also made of steel.

For infrastructure

- Transport networks: steel is required for bridges, tunnels, rail track and in constructing buildings such as fueling stations, train stations, ports and airports. About 60% of steel use in this application is as rebar and the rest is sections, plates and rail track.

- Utilities (fuel, water, power): over 50% of the steel used for this application is in underground pipelines to distribute water to and from housing, and to distribute gas. The rest is mainly rebar for power stations and pumping houses.

Benefits of using steel in construction

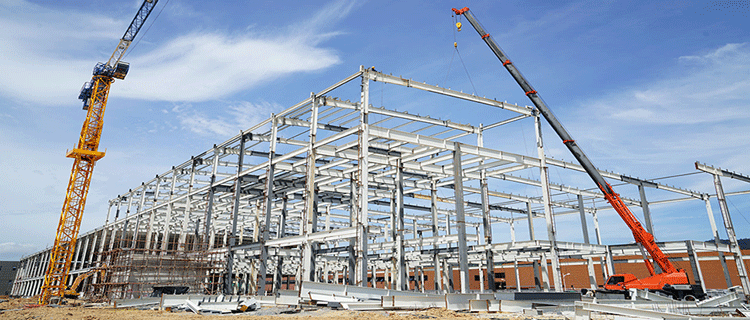

Safety

With up to 70% labour reduction possible using a steel solution compared to alternatives, fewer people equals a safer construction site. Prefabrication and dedicated lifting points on assemblies make for defined well-controlled erection processes. Steel decking and integrated edge protection facilitate safer working platforms.

Value for money

Faster construction means earlier handover and tenancy. Smaller member sizing (in particular, columns) equals greater net lettable space. Longer spans equates to more flexible internal spaces.

Robustness and ductility

Steel is an inherently ductile material, responding to overload in a controlled fashion with managed load retention. The size and shape of steel members can be configured to provide a level of structural robustness not easily achievable with other more brittle construction materials.

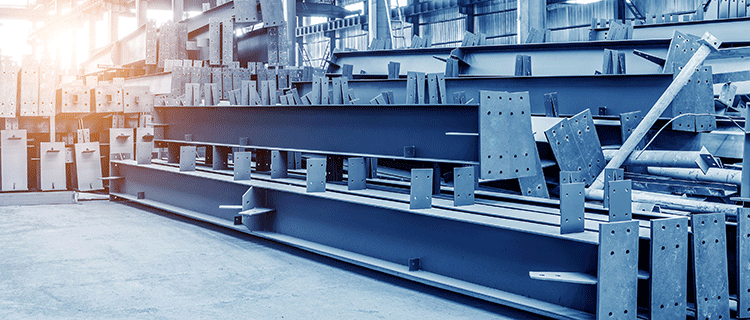

Prefabrication

Prefabrication of structural steelwork is the ‘business as usual’ case. Prefabrication brings fabrication shop control over quality and the dimensional accuracy of computer numerical control (CNC) machinery. Precise control over quantities reduces waste and workflows incorporating seamless integration back to the 3D design models ensure errors are minimised and architectural intent preserved.

Reduced weight

A steel structure is intrinsically lighter than an equivalent concrete structure due to the higher strength and stiffness of steel. With lightness comes reduced load on foundations, hence smaller foundations and an ability to perform better for some ground conditions. Weight reduction enables retrofitting onto existing structures for extension or refurbishment. Adding extra floors to existing structures is a common example.

Configuration adaptability

Given steel is assembled on site, typically with bolted connections, it’s easy to reconfigure steel elements to suit adaption of the building or structure to different purposes. The clear lines of load transfer allow strengthening and retrofitting with straightforward on-site welding. Reduced weight allows for additional floors or extensions on existing buildings. Large spans facilitate future repurposing of internal spaces with no or minimal structural modification.